Schaeffler India launches ‘OPTIME’ making condition monitoring cost-effective for all plant assets

- Schaeffler OPTIME: Comprehensive and automated condition monitoring, putting an end to unplanned downtime

- Highly scalable wireless IoT solution

- Easily integrates several hundred assets in a single day

- Cost savings of up to 50 percent compared with manual offline measurement

Pune | October 14, 2020 | Leading industrial and automotive supplier (BSE: 505790, NSE: SCHAEFFLER launched a new product called ‘OPTIME’. It is an efficient and easy-to-use low-cost solution designed specifically for comprehensive condition monitoring of all process-critical assets across entire machine and equipments. Schaeffler OPTIME provides automated condition monitoring at a cost-effective but efficient manner making it very convenient for maintenance personnel and facility operators. The India launch of OPTIME is a part of the overall launch in the entire Asia Pacific region.

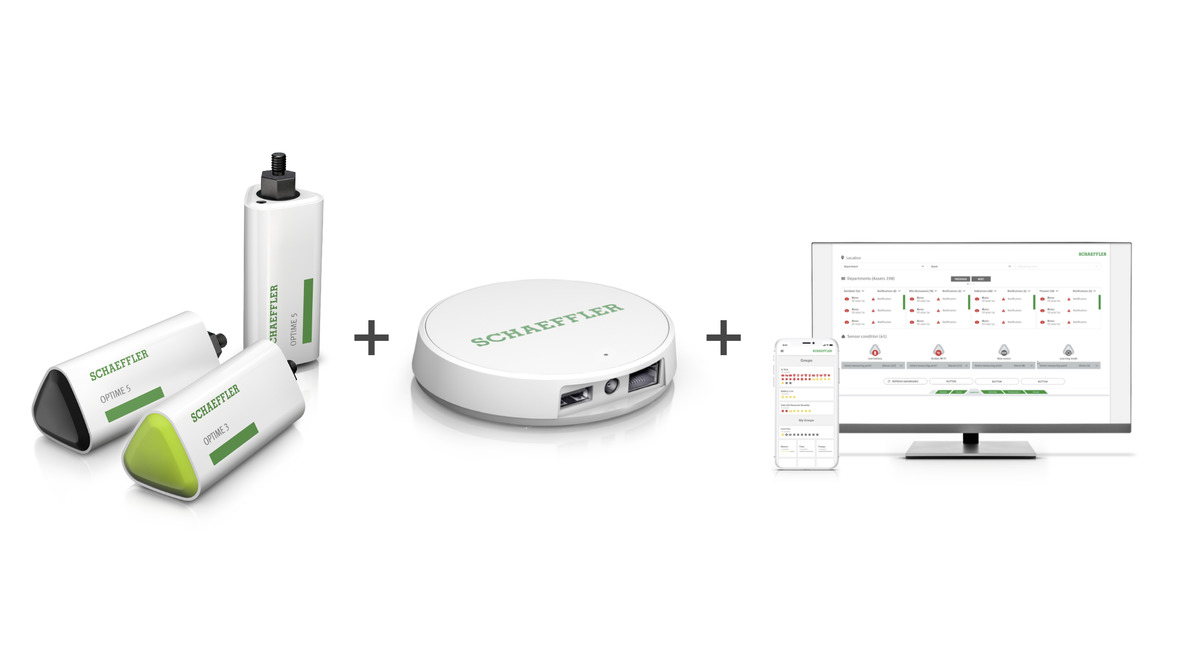

OPTIME is an easily scalable system that consists essentially of wireless, battery-powered vibration sensors, a gateway, and an app to visualize the resulting analysis data. The data captured by the sensors are analyzed using specially developed algorithms that draw on Schaeffler’s technical expertise, which is developed and refined over many decades. OPTIME provides several weeks’ early warning of damage to machine components such as electric motors, fans, and pumps. It also provides early warning of imbalances, misalignments, and knocking.

Introducing the product Mr. Harsha Kadam, CEO, Schaeffler India and President Industrial Business, said, “The impact of unplanned downtimes are far more damaging than revenues alone, and brings forth multiple challenges in any manufacturing or processing unit. For cost reasons, permanently installed continuous condition monitoring systems are typically used only for production machines that are directly process-critical. Therefore, in process and automation industries, it is not uncommon for up to 95 percent of all assets in a production facility to be either totally unmonitored or monitored only periodically by means of route-based, manual measurements. With Schaeffler OPTIME, however, comprehensive and automated condition monitoring is now a cost-effective proposition for maintenance personnel and facility operators.”

He further added that, “With OPTIME, in-house maintenance crews and external service contractors receive specific recommendations on the remedial steps required, so they can easily plan their maintenance work, manpower requirements, and spare parts procurement in a timely and cost-efficient manner.”

Technical Description:

OPTIME can be installed and initial operation carried out without any prior condition monitoring expertise, and several hundred measuring points can easily be set up in the space of a single day. The vibration sensors are attached to the monitored assets by means of screws or adhesive, and are activated by the accompanying app, which connects to them via near-field communication (NFC). All installed sensors communicate autonomously with each other and the gateway, thereby forming a dedicated mesh network that ranks among the most reliable and energy-efficient types of IoT networks in use in industry today. The sensors in the mesh network transmit machine KPI data and raw vibration and temperature data via the gateway to the Schaeffler IoT Hub. The hub analyzes the data, and the results are displayed in the app, which supports a very wide range of end devices commonly used by maintenance teams and plant operators. Alternatively, the analysis results can be made available for integration into the customer’s own IT environment via a REST API.

The app provided along with Schaeffler OPTIME presents trends in graph form and visualizes the severity of incidents using traffic light colours, alarm states, and other information. Assets can be grouped according to users’ requirements, and their condition can be presented in a range of user group-specific views.

Cost savings of up to 50 percent:

OPTIME can yield cost savings of around 50 percent compared with monthly offline measurements made using hand-held devices. It also provides better-quality monitoring than most wireless online CMS systems thanks to its complex, algorithm-based analytics. Moreover, OPTIME can be used for a multitude of assets for which condition monitoring was previously not commercially viable, which makes it the first solution capable of providing an overview of machine states that is truly comprehensive and encompasses all subsystems and auxiliary assets. This is important, because the automated condition monitoring of all assets is fundamental to the reliable prevention of unplanned machine and plant shutdowns.

About Schaeffler India Limited

Schaeffler has been present in India for over 50 years. With 3 well known product brands LuK, INA and FAG, 4 manufacturing plants and 11 sales offices, Schaeffler has a significant presence in India. Schaeffler is among the largest Industrial and Automotive supplier with sales of INR 43.6 billion in 2019 and around 2800 employees. The manufacturing plants in Maneja and Savli (Vadodara), produce a vast range of ball bearings, cylindrical roller bearings, spherical roller bearings and wheel bearings that are sold under the brand name of FAG. The plant at Talegaon near Pune, manufactures engine and powertrain components for front accessory drive system, chain drive systems, valve train, gear shift systems and a range of needle roller bearings and elements, under the brand INA. The fourth manufacturing location is based out of Hosur, producing a wide range of clutches and hydraulic clutch release systems for passenger cars, light commercial vehicles, heavy commercial vehicles and tractors sold under the brand of LuK. Schaeffler also has the largest after-market networks serving the industrial and automotive customers. All of this is backed by dedicated engineering, research and development support based in India in support of product teams.